Every year, over 1.3 million medication errors happen in U.S. hospitals. Many of these aren’t caused by careless staff-they’re caused by human mistakes that even the most experienced pharmacists can’t catch alone. That’s where barcode scanning comes in. It’s not magic. It’s not flashy. But in pharmacies, it’s one of the few tools that actually stops the wrong pill from ending up in the wrong patient’s hands.

How Barcode Scanning Works in a Pharmacy

At its core, barcode scanning in pharmacies is about verification. When a pharmacist pulls a medication from the shelf, they don’t just grab it and hand it over. They scan two things: the patient’s wristband and the barcode on the medication package. The system checks if the drug, dose, route, and time match what was ordered for that specific person. If it doesn’t match? The system stops everything. No scan, no release.

This process enforces the five rights: right patient, right medication, right dose, right route, right time. Before barcode scanning, pharmacists relied on double-checks-another person looking over the prescription. But studies show manual checks catch only about 36% of errors. Barcode systems catch 93.4%.

The technology uses either 1D barcodes (the classic black-and-white lines) or 2D matrix codes (square patterns that hold more data). Most medications still use 1D codes with the National Drug Code (NDC), but newer packaging is shifting to 2D codes that can include lot numbers, expiration dates, and even batch info-all scanned in one go.

What Errors Does It Actually Prevent?

Barcodes don’t just prevent random mistakes. They stop the kinds of errors that can kill.

- Wrong patient: 92% of these errors are blocked. Imagine giving a heart medication meant for one person to someone with kidney failure. Scanning stops that.

- Wrong drug: 89% prevented. A patient gets insulin instead of metformin? The system flags it before it leaves the counter.

- Wrong dose: 86% prevented. Levothyroxine overdoses? A 10x dose gets caught because the barcode says 25 mcg, but the system expects 50 mcg.

- Wrong route: Oral pills labeled for IV use? The system knows the difference.

A Pennsylvania hospital tracked this in real time. Before barcode scanning, staff accurately dispensed meds 86.5% of the time. After? It jumped to 97%. That’s not a small improvement. That’s life or death.

Why Manual Checks Aren’t Enough

Some people think, “Why not just have two pharmacists check every prescription?” It sounds solid. But humans get tired. They get distracted. They’ve done 50 checks already that day. One slip, one misread label, and the error slips through.

Barcodes don’t get tired. They don’t miss details because they’re rushing. They don’t assume “this looks right.” They only know what the code says-and they compare it to what the system says the patient needs. If it doesn’t match, it doesn’t go out.

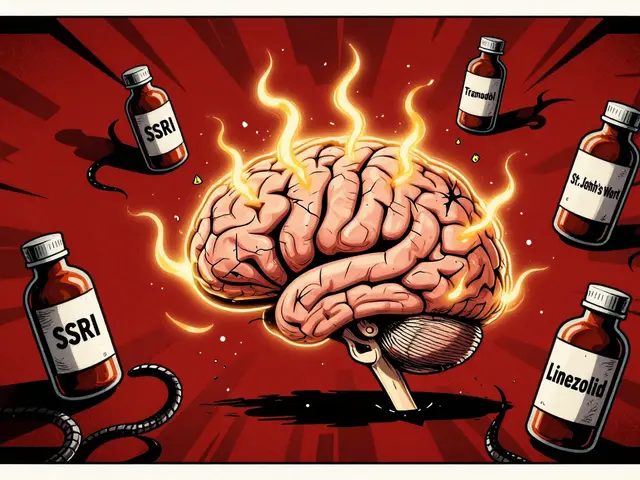

And here’s the kicker: even when pharmacists think they’re being careful, they’re wrong. A study found that 68% of hospitals still have staff who bypass scanning during busy times. That’s not negligence-it’s burnout. But when scanning is built into the workflow, and alerts are meaningful, not constant noise, compliance improves.

The Hidden Problems: When Scanning Fails

Barcode scanning isn’t perfect. It’s not a magic shield. It has blind spots.

Some medications-like insulin pens, ampules, or compounded drugs-don’t have standard barcodes. Or the barcode is smudged, torn, or printed poorly. In these cases, 15% of scans fail, according to ECRI Institute. When that happens, staff must stop, look at the actual medication, and compare it visually to the order. But here’s the danger: if the pharmacy printed a wrong label with a correct barcode, the system will still approve it.

There’s a real case where vancomycin was dispensed in the wrong concentration. The barcode was accurate-because the label was printed correctly by the pharmacy. But the wrong concentration was inside the vial. The scanner didn’t know. It only read the label. That’s why experts say: never trust the barcode alone when it won’t scan. Always verify by sight.

Another issue? Alert fatigue. If the system beeps for every small mismatch-even if it’s a known, harmless variation-staff start ignoring it. That’s why good systems filter out false positives and only flag real risks.

What’s Better Than Barcode Scanning?

Some say RFID or AI-powered systems are the future. RFID can track items without line-of-sight scanning, but it’s 47% more expensive per unit. And while AI can predict scanning failures, it’s still in testing. Right now, barcode scanning is the most cost-effective, proven method.

Smart pumps for IV drugs are great-but they only help with injections. Barcodes help with pills, patches, eye drops, injections, everything. And unlike RFID, barcode scanners work with existing pharmacy systems. No need to replace your entire inventory.

Compared to automated dispensing cabinets (ADCs), barcodes are simpler. ADCs store and dispense meds, but they still rely on barcodes to verify what’s being pulled. So even the most advanced systems need barcodes underneath.

Why Community Pharmacies Are Still Lagging

Most hospitals (78%) use barcode scanning. But only 35% of independent community pharmacies do. Why? Cost. A full system-scanners, software, training, integration-can cost $20,000 to $50,000 upfront. For a small pharmacy, that’s a big investment.

But the cost of not doing it? Higher. A single dispensing error can lead to lawsuits, lost licenses, or worse. One pharmacist in Perth told me, “We spent $30,000 on scanners. Last year, we avoided three potential errors. One was a child getting an adult dose of blood pressure meds. That one mistake would’ve cost us more than $500,000 in legal fees and reputation damage.”

Some vendors now offer cloud-based barcode systems with monthly fees instead of big upfront costs. That’s making adoption easier for smaller shops.

What Needs to Change for This to Work

Technology alone won’t fix safety. People have to use it right.

- Scan the manufacturer’s barcode, not the pharmacy’s label. Pharmacy labels can be wrong. The original package barcode is the source of truth.

- Train staff on what to do when a barcode won’t scan. Don’t just force-scan or skip it. Have a visual verification protocol.

- Review scanning data monthly. Which meds are most often scanned incorrectly? Which ones are skipped? Fix those patterns.

- Use specialized trays for small vials and ampules. A good tray holds the item steady and improves scan success by up to 40%.

And here’s the most important thing: never let scanning replace human judgment. The system is a safety net. Not a replacement for your eyes, your brain, or your training.

The Future Is 2D

Right now, only 22% of medications use 2D barcodes. But by 2026, that number is expected to jump to 65%. Why? Because 2D codes can store way more data. Imagine scanning a vial and seeing not just the drug name, but its expiration, storage temp, and whether it’s been recalled-all in one scan.

The FDA is already testing 2D barcodes in pilot programs. Epic Systems and Cerner are building AI tools that predict which barcodes will fail before they’re even scanned. In the next five years, scanning won’t just prevent errors-it’ll predict them.

Final Thought: It’s Not About Technology. It’s About Trust.

Barcode scanning isn’t popular because it’s cool. It’s popular because it works. It doesn’t promise perfection. But it cuts the most dangerous errors by over 80%. That’s not just a statistic. That’s a child who didn’t get the wrong dose. That’s a senior who didn’t have a stroke from a drug interaction. That’s a pharmacist who didn’t lose sleep wondering if they made a mistake.

It’s not about having the fanciest scanner. It’s about making sure every single time a pill leaves the pharmacy, it’s the right one. And for that, barcode scanning is still the best tool we have.

Do all medications have barcodes?

Most prescription medications in the U.S. have barcodes because of the FDA’s 2006 Bar Code Label Rule, which requires the National Drug Code (NDC) to be printed in barcode format on all unit-dose packages. However, some medications like compounded drugs, insulin pens, ampules, and emergency medications may not have standard barcodes. In these cases, pharmacists must visually verify the medication against the prescription.

Can barcode scanning prevent all medication errors?

No. Barcode scanning prevents about 93% of dispensing errors related to wrong patient, drug, dose, or route-but it can’t catch everything. If a label is printed incorrectly with the right barcode (e.g., wrong concentration in a vial), the system will approve it. It also doesn’t detect allergies, drug interactions, or incorrect dosing based on patient weight. That’s why visual verification and clinical judgment are still essential.

Why do some pharmacists bypass scanning?

Many pharmacists skip scanning during busy shifts because scanners fail-barcodes are smudged, small vials are hard to scan, or the system freezes. Others do it because they’ve seen the system make false alarms before. But studies show that when scanning is made easy (with better trays, mobile scanners, and fewer false alerts), compliance improves dramatically. Training on proper escalation procedures also reduces bypassing.

Is barcode scanning worth the cost for small pharmacies?

Yes, if you dispense prescriptions regularly. While upfront costs can be $20,000-$50,000, the cost of a single dispensing error-legal fees, loss of license, or patient harm-can be far higher. Many vendors now offer cloud-based systems with monthly subscriptions, making it more affordable. Even small pharmacies report avoiding 1-2 major errors per year after implementation, making it a clear ROI.

What’s the difference between 1D and 2D barcodes in pharmacies?

1D barcodes (like UPC codes) store basic info like the NDC number. 2D barcodes (matrix codes like QR codes) can hold much more: lot number, expiration date, manufacturer, even storage instructions. 2D codes are more reliable when partially damaged and are becoming the standard. By 2026, 65% of medications are expected to use 2D barcodes, up from just 22% in 2023.

Allison Turner

November 28, 2025 AT 03:38Look, I get it, barcodes sound fancy. But let’s be real-half the time the scanner beeps for no reason, then the pharmacist just slaps a pill in a bag and calls it a day. I’ve seen it. I’ve been the patient. It’s not magic. It’s just another box they check while rushing to the next one.

Darrel Smith

November 28, 2025 AT 12:20THIS is why America is falling apart. We’ve outsourced our responsibility to machines. A human being used to look at a prescription, think about it, and make sure it was right. Now? We let a barcode do the thinking. And when that barcode is wrong-because someone printed the label wrong or the scanner glitched-we just shrug and say ‘the system said it was fine.’ No accountability. No conscience. Just a machine that thinks it knows better than a person who’s been doing this for 20 years.

And don’t even get me started on how they skip scans during ‘busy times.’ That’s not burnout-that’s surrender. We’re letting fear of liability replace actual care. And the worst part? The companies selling these systems are making bank while real pharmacists are getting burned out trying to keep up. It’s not safety. It’s corporate theater.

Aishwarya Sivaraj

November 29, 2025 AT 12:51i read this and thought about my grandma who got the wrong blood pressure med last year because the barcode was smudged and the tech just guessed it was close enough. she ended up in the er. barcodes help but they are not perfect. the real hero is the pharmacist who stops to look at the pill even when the machine says it’s fine. we need better training not just better tech. also 2d codes are the future but we need to make sure small pharmacies can afford them. its not just about money its about trust. trust in the system and trust in the people using it. please dont forget the human in the loop.

Iives Perl

November 30, 2025 AT 21:21Barcodes are a distraction. The real story? The FDA and big pharma are using this to track every pill you take. That’s not safety-that’s surveillance. You think they care if you get the right dose? Nah. They care if they can link your meds to your insurance, your doctor, your habits. Next thing you know, your policy gets raised because you ‘took too many painkillers.’ Scanners are just the tip of the iceberg. 🤫👁️

steve stofelano, jr.

December 2, 2025 AT 15:54While the technological implementation of barcode scanning in pharmaceutical dispensing represents a significant advancement in patient safety protocols, it is imperative to recognize that such systems function optimally only when integrated within a culture of clinical diligence and procedural adherence. The empirical data presented in this article substantiates a statistically significant reduction in dispensing errors; however, the persistent human factors-such as workflow disruption and alert fatigue-must be addressed through organizational training paradigms and ergonomic design improvements. Furthermore, the transition to 2D barcoding should be supported by equitable funding models to ensure universal access across all healthcare settings, irrespective of institutional size or fiscal capacity.

sharicka holloway

December 3, 2025 AT 00:49My uncle’s a pharmacist in rural Ohio. He told me he used to do double-checks until his hands hurt. Now he scans. Says he has time to actually talk to patients now. That’s the real win-not just fewer errors, but more care. It’s not perfect, but it’s better. And if we make it easier for small shops to use it, we all win.

Alex Hess

December 3, 2025 AT 12:26This article reads like a corporate ad. Barcodes don’t prevent errors-they just make pharmacists feel better about skipping real clinical judgment. And the 93% stat? Probably cooked by vendors who sell the scanners. Real safety comes from staffing, training, and respect-not a damn barcode.

Rhiana Grob

December 4, 2025 AT 09:18Thank you for writing this with such clarity. I work in a hospital pharmacy, and I’ve seen firsthand how scanning has changed our days-not by replacing us, but by letting us focus on what matters: the patient. The moment a scan stops a dangerous error? That’s when you feel the weight lift. It’s not perfect, but it’s the best tool we have. And if we fix the small things-better trays, smarter alerts, training that doesn’t feel like a chore-we can make it even better. Let’s not throw the baby out with the bathwater.